2024 Model 600 HP Truckable Push Boat For Lease

| Ad Number: | 932 |

| Year: | 2024 Model |

| Model: | TRUCKABLE BOAT TUG |

| Length: | 25’-3” LOA |

| Beam: | 24' w/ optional fenders |

| Light Draft / Max Draft /Light Ship Weight/: | 6' |

| Propulsion/ Props/: | Two John Deere 6068 AFM85 diesel engines, 300 HP each@ 2500 RPM (M3 rating) connected to two Twin Disc MG-5075 with 2.88:1 ratio Two 21/2² Aquatech 17 stainless steel propeller shafts with two 34”x18” x 4 blade bronze propellers |

| Overstock Price: | Lease or Lease to Purchase |

| Fuel Capacity, Transfer Rate, Lube Oil: | Approximately 350 gallons |

| GT/NT/ Bollard Pull & Towing Equipment: | 44,000 # (approx.) (w options 42,000#) |

| Electronics: | ELECTRICAL SYSTEM: Two 12-volt heavy-duty 8D marine batteries mounted in Coast Guard approved engine room battery box. One 12 VDC light shall be installed in the engine room. NAVIGATION LIGHTS: Mast on top of pilot house shall have two white tow lights forward and two amber tow lights aft. Green and red sidelights shall be installed on the side of the pilot house. |

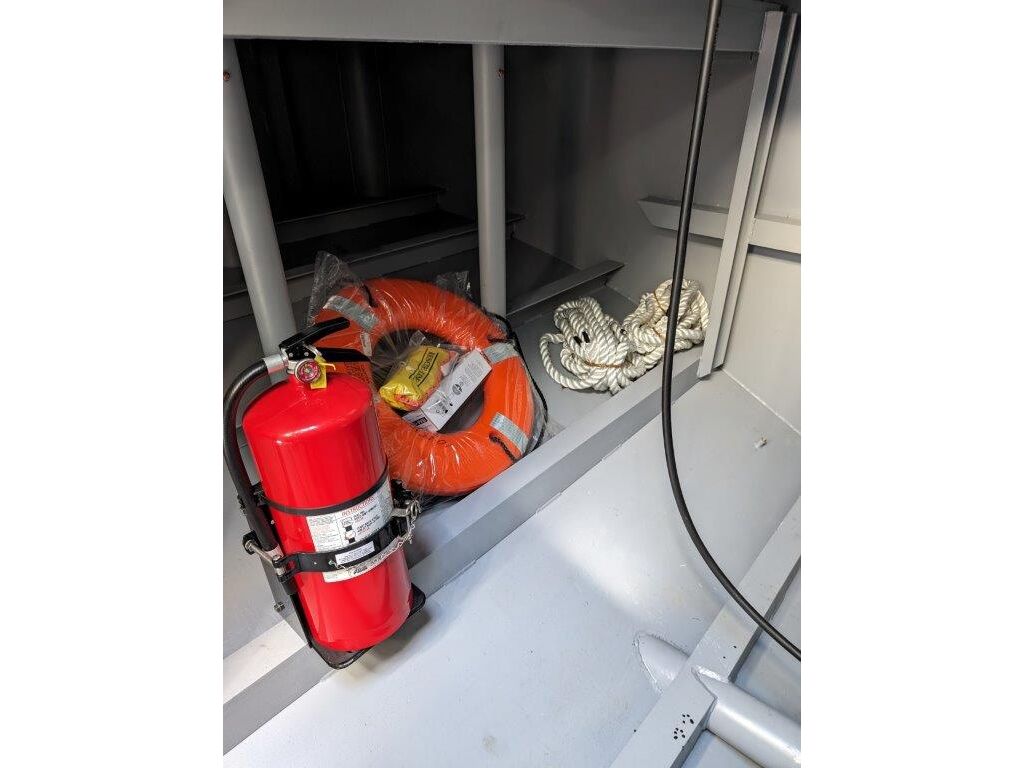

| Class/ Life Saving Equipment: | BILGE PUMP: Two 12 volt 1,000 GPH pumps. |

| Boat Location: | USA- Approx July 2024 Completion |

Special Features: EYE-LEVEL: 15’-6” from inside of pilothouse. FLANKING RUDDERS: Two main steering rudders and four flanking rudders shall be installed. Rudderstocks shall be 2² cold drawn steel in bronze bushings. Rudders constructed of ¼² steel plates with 3/8² x 2² flat bar bracing. Steering gear on aft deck shall be covered with yellow fiberglass grating. All new steel prime to ASTM A-36. PUSH-KNEES: Constructed of ¼” plate with steps and handrail on one side. Overall height shall be 9’ with upper 3’ removable for shipping. Pads are 2² thick rubber bonded to ½² x 10² steel backing plate. WINCHES: Two 5-ton manual winches shall be installed on the forward deck. 5/8” x80’ of cable with a 4’ eye on one end shall be installed on each winch.

| |

| Contact Us: | Email Us |

| Call Us: | Bob - 954.224.2628 |

2024 MODEL TRUCKABLE WORK BOAT

STEEL: All new steel prime to ASTM A-36.

SHELL PLATING: Deck shall be ¼” plate. Sides, bottom, head log and transom of 3/8² steel plate. The four corners shall be ½” thick pipe x 5.375” radius.

FRAMING: Deck framed with 3² x 3² x ¼² angle on 24² centers. Sides framed with 3² x 3² x ¼²angle on 20² centers. Bottom framed with 4² x 3² x ¼² angle on 20² centers. Welding on all frames shall be 3” on 12” centers.

BULWARKS: Continuous all-around hull. Bulwarks extend 14² above deck and flanged 2” built from ¼” plate and brackets.

FENDERS: 20' x ½" x 4' flat bar down each side of hull. Head log and the four corners shall have 10” x36” push knee fenders installed. Install guards on fenders in 6 places.

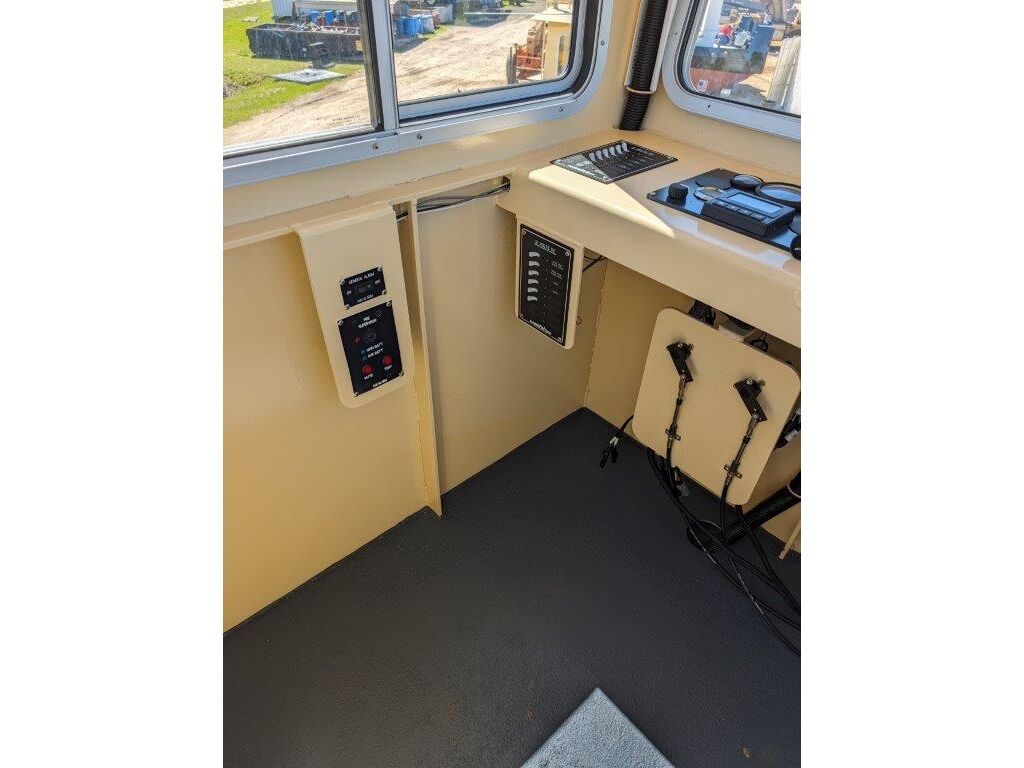

PILOTHOUSE: Pilothouse is 4'6² wide x 4' long x 6' 9² high and is constructed of 3/16² steel plate with sloping forward window and visor around roofline. The pilot house is elevated on a 9' pedestal. One overhead cabin light shall be installed. Two six-gang 12-volt breaker panels mounted in dash of pilothouse. Front window 4¢ x 3¢ horizontal slide. Side windows are 3¢ x 3¢ horizontal slide and rear windows are 15² x 30² vertical slide with one of these mounted in 6¢ x 2¢ steel door. All windows are tempered safety glass. One 7² sealed beam searchlight and one single-bugle horn mounted on pilothouse top.

ENGINE HOUSING: Engine room housing is 8' long by 9' wide by 27" above deck. Constructed of 3/16" plate and framed with 3/8² x 2" flat bar. Overhead framed with 3² x 3² x ¼² angle. The housing cover is removable for complete access to the engine room.

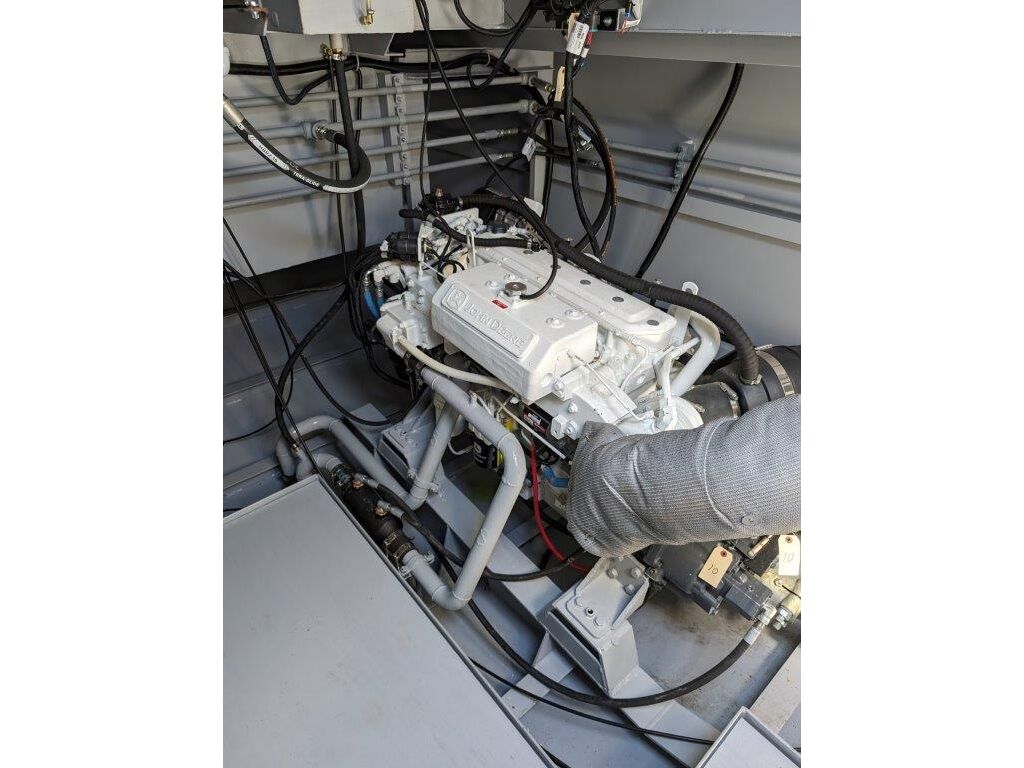

POWER TRAIN: Two John Deere 6068 AFM85 diesel engines, 300 HP each@ 2500 RPM (M3 rating) connected to two Twin Disc MG-5075 with 2.88:1 ratio shall be installed. Two 21/2² Aquatech 17 stainless steel propeller shafts with two 34”x18” x 4 blade bronze propellers shall be installed. Two 21/2² Cutlass stern bearings shall be installed. Two PYI packless shaft seals or standard stuffing boxes with containments and pump shall be installed. Exhaust installed through stacks mounted on engine box top through 5” “cowl” spiral exhaust silencers, residential quiet.

ENGINE COOLING: Closed freshwater system circulated through 7" x 9.8" channel welded to bottom of hull. System is air pressure tested for integrity before painting.

FUEL TANK: Fuel tank capacity is approximately 350 gallons and is air pressure tested before installation. The fuel tank has a vent pipe and 2-½² fill pipe and valve for fuel shut off. Emergency fuel shut off outside engine room shall be installed.

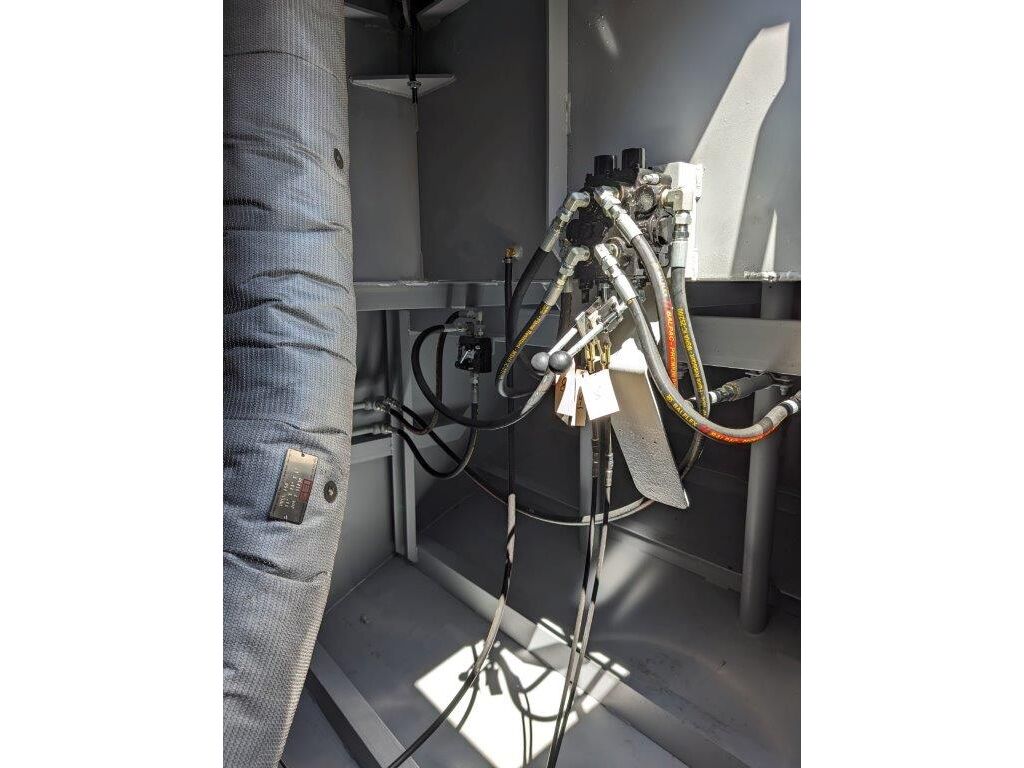

HYDRAULIC STEERING: Two hydraulic pumps, one driven off each main engine. Control valve and flow regulator mounted in engine room

ENGINE CONTROLS: Single lever control head with heavy-duty 43C control cables.

BITTS: One double towing bitt, one single head bitt, and four single quarter bitts.

LIFTING EYES: Four permanent eye straps welded to hull.

ANODES: Four 12-pound magnesium anodes shall be installed on the bottom aft.

PAINT SYSTEM: All plates and shapes shall be blasted and coated with a pre-construction primer. Exterior hull, decks and pilot house shall be sprayed with epoxy paint. Hull below the waterline and the deck shall be sprayed with one coat epoxy topcoat. Hull above the waterline and house shall be painted with one coat of polyurethane paint. Engine room sprayed with one coat of epoxy topcoat. The paint manufacturer shall be Sherwin Williams or equal. Main deck and top of engine cover shall have non-skid deck. Colors: hull black, superstructure tiger tan, decks dark gray, trim Newt green and engine room gray. Apply name and hailing port.

A Disclaimer:

While we attempt to display current and accurate data, this listing may not reflect the most recent transactions or may contain occasional data entry errors.

Selling agent makes no warranties, express or implied, regarding the content or today's availability of the products described herein. All equipment and statements listed are subject to today's availability, classification, certification changes, contract in progress or prior sale. Photographs may be representative only, may feature optional equipment offered at extra cost and may vary somewhat from the actual items offered for sale.